Automation of Repair Processes in the Jewelry Industry

In a world where efficiency and time management are becoming increasingly important, automation is hardly thinkable anymore. This also applies to the jewelry industry, where the automation of repair processes can have a significant impact. Let’s discuss the benefits of this.

Benefits of Automation

Automation reduces human errors and increases consistency in repairs. By using high-quality machines and software, manual and sometimes error-prone processes are replaced by standardized solutions, resulting in less variability of results.

In addition, automation saves time. Tasks that previously took hours, such as engraving personal messages or accurately cutting gemstones, can now be completed in minutes thanks to fast and precise machines.

Pro tip: Consider automating common repairs such as resizing rings or polishing jewelry to quickly reap the benefits of time savings.

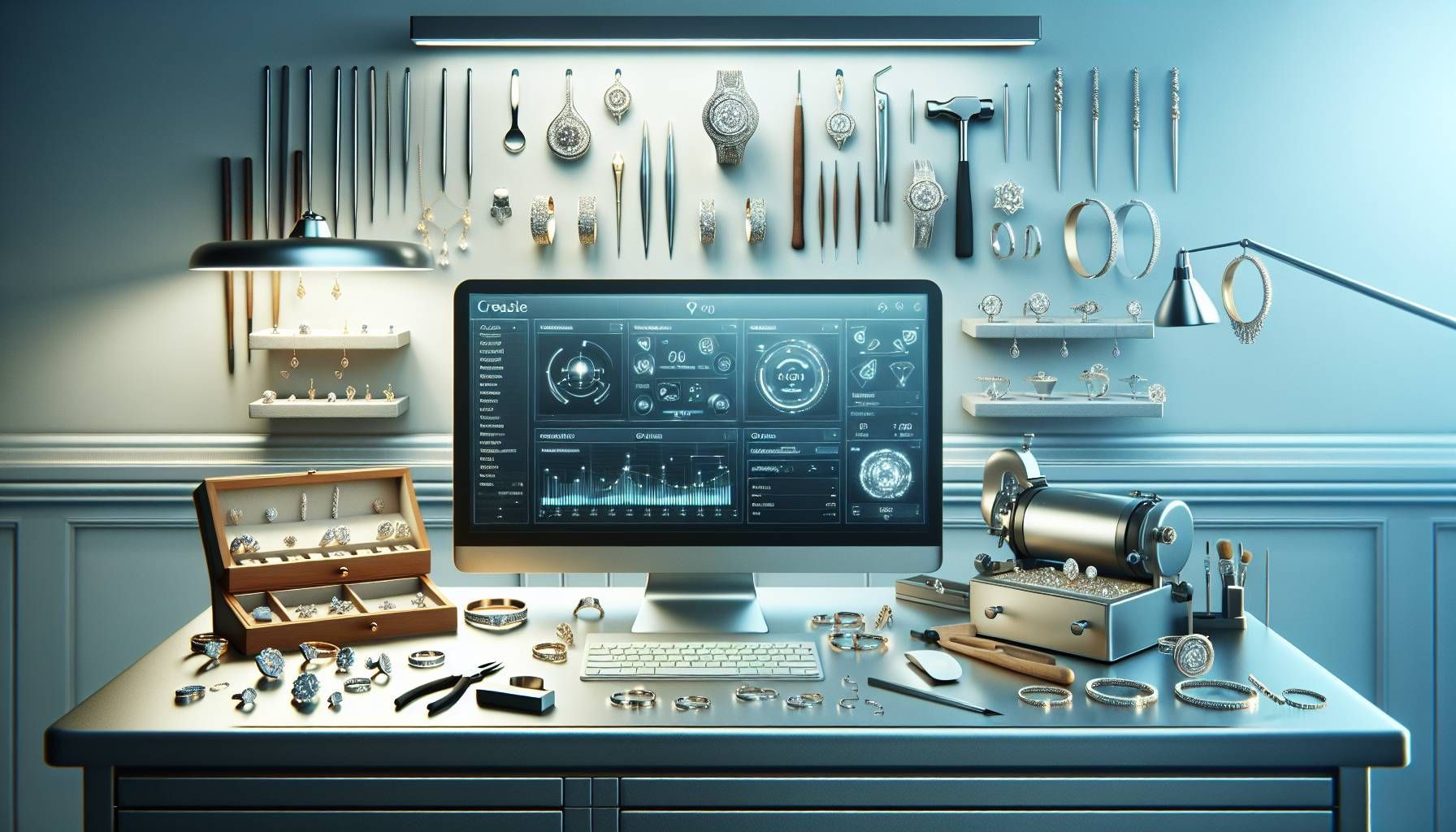

The Latest Technologies in Jewelry Repair

Technology in the field of jewelry repair is developing at a rapid pace. Here are some of the latest innovations supporting the jewelry industry.

Laser Welding

This technique uses a concentrated beam of light to precisely weld metal without heating the surrounding areas. Laser welders are ideal for delicate repairs and can perform renovations without noticeable signs.

CNC Machines

CNC or Computer Numerical Control machines are used for accurately cutting and machining gemstones and metals. This technology enhances the precision of cutting and machining processes.

3D Printing

With 3D printing, jewelers can create complex designs and models that would otherwise be nearly impossible to achieve with traditional methods. This is particularly useful for restoring antique or unique pieces.

Laser welders and CNC machines may require significant initial investments, but the long-term time and cost savings are worth it.

Cost Control Through Automation

Cost savings are an important benefit that automation brings. But how does automation in the jewelry industry precisely help to control costs?

By transferring repetitive and labor-intensive tasks to machines, labor costs can be significantly reduced. This means staff can focus on specific, highly specialized tasks that require true craftsmanship.

Moreover, automation reduces waste and prevents material loss. Machines like CNC cutters and laser cutters are extremely precise and ensure that every millimeter of precious material is utilized.

Pro tip: Conduct a cost-benefit analysis before investing in automation technology. Evaluate the initial costs against the expected savings over a certain period.

How Automation Improves Customer Service

One of the lesser-known benefits of automation is the positive impact it can have on customer service. Customers expect not only high quality but also fast and reliable service.

With faster repair times, jewelers can serve their customers more smoothly, leading to increased customer satisfaction. Customers who see their jeweler using the latest technology often have more confidence in the professionalism and craftsmanship of the business.

Automation also helps track repair orders. With automated repair processes, jewelers can easily monitor the status of each repair and quickly provide customers with updates.

Pro tip: Use specialized order management software to automatically send status updates to customers, further improving communication and customer satisfaction. You may read more about the jeweler solution.

Integrating Automation into Your Business

Integrating automation into your business may seem overwhelming, but with a systematic approach, the software implementation can be achievable and rewarding. Here are some steps to ensure a smooth transition.

Step 1: Evaluation and Planning

Analyze your current workflows and identify the tasks that will benefit most from automation. Create a clear plan with goals and KPIs to measure success.

Step 2: Find the Right Tools

Research and select the technologies and machines that best meet your business needs. Consider options such as leasing or financing to reduce the financial burden.

Step 3: Staff Training

Although automation facilitates many tasks, it is essential that your team is well-trained in the new technologies. Schedule training sessions and workshops to familiarize them with the new processes.

Pro tip: Involve your team in the planning process and ask for feedback. This ensures better acceptance and adaptation to the new technologies.

Looking Ahead: The Future of Jewelry Repairs

The future of jewelry repairs looks promising due to ongoing technological advancements. We can expect processes to become increasingly advanced, faster, and cost-effective.

Artificial Intelligence (AI) and machine learning will play a greater role in automated repair processes. This could lead to predictive maintenance and improvements in the precision of repairs.

Additionally, nanotechnology is expected to become more inclusive in the jewelry industry, making it possible to perform repairs at a molecular level. The possibilities are endless, and jewelers who adapt now will be ready to benefit from these future innovations.

Pro tip: Stay updated on the latest developments in technology and innovation. Attend trade shows, follow industry magazines, and participate in webinars to keep your knowledge current.

Conclusion

Automation offers numerous benefits for the jewelry industry, from cost savings and increased efficiency to improved customer satisfaction and advanced repair capabilities. Although the initial investment may be significant, the long-term benefits often far outweigh the costs.

By investing in the latest technologies and properly training your staff, you can elevate your business to a higher level while optimally responding to your customers' expectations. Keep innovating and looking ahead to stay ahead of the competition and become a leader in the industry.

Take your store to the next level

Start automating and digitizing your store processes today. PrismaNote helps retailers with this. Discover what we can do for you via the menu above.

- George